In order to minimize the issues being faced by the company, Sia Meng, the executive director of the company is considering several options in order to manage their bottom line profits and to smoothly run its operations while retaining the confidence of employees.

Alternative 1

The first option is to reduce the number of model being manufactured by the company to the levels that were being produced in 1996 or 1998, as this will reduce the amount of inventory being hold by the company. Furthermore it will also decrease the need of keeping different raw materials and the safety stock requirements, with fewer SKUs; the company will be better able to increase its fill rate. However on the negative sides this option will create difficulty for the company, by making it less attractive for the dealers due to limited variety, and there is a possibility that the dealers might drop the products of Four Star industries in order to stay competitive.

Alternative 2

The second alternative is to insist the dealers to order minimum number of mattresses corresponding to the batch size for each of the model they place an order for, as this will reduce the level of inventory needed to be kept by the company. In this way, the company will not be required to produce a complete lot of mattress in order to meet the requirement of 1 unit. Additionally this would setup a pull system that will benefit the company to meet the orders from their work in process inventory. However this option will discourage the dealers from selling the products of Four Star industries as it will force dealers to hold certain level of inventory which they might not be willing to do say.

Alternative 3

Third alternative is to reduce the requirement of safety stock for the finished mattresses. This approach is very general as of stock out is mainly a result of unpredicted demand more specifically in slow moving mattresses. So there is a possibility that reducing the safety stock might not resolve the issue of stock outs. On contrary this step will make the situation more miserable. Furthermore it is also not feasible for the company to increase the level of safety stock for slow moving mattresses as it might prevent the stock out for a certain period of time but will eventually increase the level of inventory; making it least considerable.

Alternative 4

The last option is to re-allocate the manufacturing function to a cheaper oversea location. This option will help the company in reducing its cost associated with the operations in the long run while making the company cost effective in comparison to its competitors. However this option might not resolve the issue of stock out and will lead to increased delivery time and might affect the quality of the products.

Recommendation

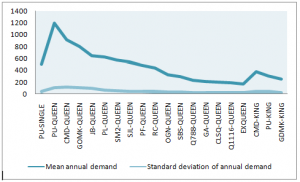

None of the above options seem to be viable for the company as they will not resolve the fundamental issues being faced by the company, such as; production scheduling, order fulfillment and inventory management. Therefore it is recommended that the company should implement the assembly to order production process and should bring down the number of models to the fastest moving mattresses only (Exhibit 2). This will help the company in forecasting the demand much more easily mainly due to low variability in demand, resulting in efficient inventory management and a major decline in the stock outs. Furthermore it will increase the rate of order fulfillment by allowing the company to be more flexible with the changes being demanded by the dealers and in meeting the needs of the customers. Apart from that, in order to remain competitive; the company should form strong relationship with the dealers, as they possess strong bargaining powers and play a critical role in terms of creating a demand among the customer.By giving them the authority and responsibility; the company can build a strong bond with them, that will eventually benefit the company in bringing their products forward by creating a need among the customers through dealers. (B.V., 1984)

Risk and implementation

This implementation of assemble to order process might result in the potential loss of large and small dealers due to limited number of model being offered by the company but it will definitely make the entire process much more efficient.

The loss of potential dealers can be overcome by establishing strong bonds with the dealers by offering them lucrative deals to keep them motivated in showcasing the products being produced by the company.

Implementation plan

- Increase flow of information between the dealers and the managers as this will help in analyzing the demand of the mattress more accurately.

- Creating strong bond with dealers by developing a strong relationship and by providing them with lucrative offers in order to keep them motivated.

- Developing a responsive supply chain in order to meet the needs of dealers on timely manner.

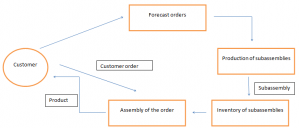

- Implementation of assemble to order process in order to reduce the stock out issue being faced by the company. (Exhibit 1)

- Analyzing the trend of the each of the fastest selling model in order to better forecast the demand.

- Developing a feedback score board in order to gain the feedback of the dealers as well of the potential customer.

- Discovering alternative markets in order to shift the manufacturing function to a cheaper oversea location after getting the manufacturing process in control.

Exhibits

Exhibit 1: Assemble to order

Exhibit 2: Annual demand and variation of fast moving mattress

This is just a sample partical work. Please place the order on the website to get your own originally done case solution.