Dawson Forest Products, Inc. Case Study Analysis

Option 5 is to Enhance Raw Material/Drying Environment Uniformity and Gas-Powered Kiln Energy Efficiency

By choosing this alternative, present gas-powered kilns might be made more effective. The kilns’ construction and insulation might be improved, leading to quicker, more effective drying times and higher-quality production down the line. The technique would also alter in a few ways. Pre-sorting wood by species, weight, or moisture content allows for precise timing of the drying process and guarantees uniform drying.

Pros

- Less initial investment;

- Use of existing resources;

- Improved product quality;

- More quality control; and

- Less fuel needed to heat kilns are all benefits.

Cons

- GHG emissions;

- No benefit from credit offsets;

- Longer processing time to sift through wood; and

- Loss of capital used for biomass conversion.

Recommendation

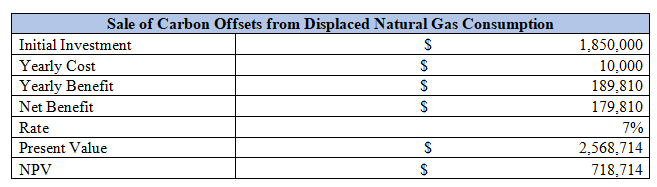

I would advise Dawson Forest Products to pursue Option 1 which is the Biomass Conversion Project (See Appendix 1 and 3). The mill, as well as the larger forestry products industry, will need reform given the track record of the BC government and the federal government’s commitment to climate change efforts and GHG reduction aims. The goal of the government is to persuade major GHG emitters to change their approach to reducing pollution.

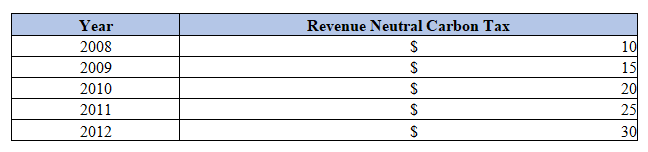

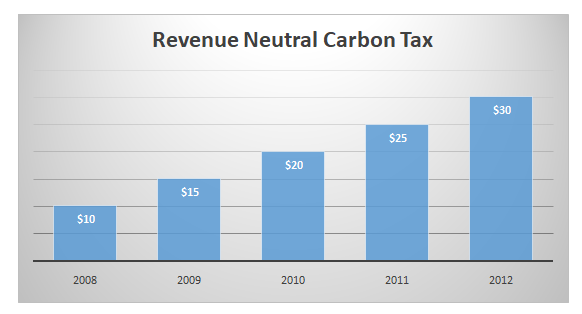

The main factors causing change are sustainability and accountability, and businesses that donot comply with the government’s goals for reducing carbon emissions will suffer the consequences. Very likely to the point of bankruptcy and/or having no profit margins. Operational costs will continue to climb until adopting “greener” practices is the only option to remain in operation. It would be better for the mill to complete the biomass conversion project in order to continue functioning because the provincial government’s course shows no signs of shifting. The trend of carbon taxes is seen in Appendix 2.

Implementation

The biomass conversion project is put on hold as the first stage in execution so that it may be reevaluated and tackled in a more strategic manner to better control budget expenditures and lead times. The work breakdown structure, team member roles and responsibilities, supplier base, available resources, and project schedule all need to be carefully examined.

The kiln conversion and the creation and installation of the thermal energy system are the two components of the biomass conversion project that will be finished over the course of two years. Six months were allocated for the initial phase, but the intricate building procedure took much longer. Phases one and two have now each been completed for a year. The project will be managed by a separate third party from beginning to end. In order to make sure the project stays on schedule and within the allotted budget, this person will be in charge of managing the vendors, contractors, and workflow.

Monitor and Control

The key deliverables’ major milestones will be determined by the project manager. To ensure that the project stays on schedule, enough time has been allotted for each delivery. CEO Jon Reed will set up KPIs when the project is finished and the mill is running to track its success and make sure it complies with the provincial government’s GHG reduction policy. Estimated emission reductions will be reported, compared to information from the previous natural gas-powered process, and published. The company in charge of analyzing emissions is Canfor.

Energy monitoring comprises:

- Operation of thermal energy systems;

- Fuel use;

- Travel distances; and

- Modes of transportation........................