Supply Chain Partners: Virginia Mason and Owens & Minor (A): Case Study Solution

Introduction

“Virginia Mason” is a non-profit organization that is located in Seattle. It is a private organization that uses the “Owens & Mirrors” as its significant vendor’s suppliers since 2004. The company has a significant market reputation and provides broad clinical services in the western part of Washington (Brem, 2009). The company’s main vision and mission statement includes the “team medicine” as its core values, that is the company has a strong team that helps the company to sustain future growth and worth in the market. The company core values and competitive strength helps them to generate high revenues apart from the fact that the company is totally a non-profit organization. Moreover, VM is rehearsing a "Toyota Production framework" in order to attain the market position and to become the quality market leader in healthcare sector.

SWOT Analysis

In order to create strong market position, it is important to lessen and eliminate shortcomings so that the company can better compete with its rival contenders, thereby focusing on the opportunities provided by the internal and external structure of the company. Appendix 1 shows the preceding SWOT model of the organization.

Question-1

There are several problems that raised when O&M and VM had joined the business together. The O&M involved the expense in addition to evaluating strategy for the clients however VM recommended the seller to apply TSCC model for VM's exercises. Since the cost-plus model is comparatively more efficient as compared to TSCC (“Total Supply Chain Cost model”), so the organization had dealt with a great deal of issues seeing the models’ executions as both of the organization's has various perspectives in regards to the model's executions and has different visionary goals and triumph.

Question-2

O&M to meet VM necessities has been associated with the JIT (with perfect timing) and low unit measure administrations for the Virginia Manson Company. Both the organizations have considering to change the evaluating model, the model is accepted to be obsolete. The two organizations have banded together and made a TSCC “Total Supply Chain Cost”, evaluating model. TSCC is an action-based model, which appoints the stock taking care of and conveyance costs drivers to Virginia Manson, along these lines, guaranteeing O&M's productivity. The organization's senior administration accepts that the TSCC is a more financially savvy model, which would smooth out the organization's circulation exercises, straightforwardly affecting the expense.

Question-3

The significant difficulties for fostering an advanced Supply Chain the board System for different organization such as O&M in response to advanced technologies incorporates;

- Overseeing clients’ assumptions

- Re-appropriating administrations

- Movement based evaluating model

- Overseeing providers

- Keeping up with quality and supportability

- Admittance to information

- Risk relief

Question-4

The vendor of VM, O&M is currently using the “cost plus pricing basis for its clients” but it is suggested by the management of VM to the vendor to implement “Total Supply Chain Cost Model” to gauges the expense connected with VM exercises. It is suggested that the TSCC will help to find the insufficient practices that comes in the cost basis techniques. (See Appendix 4)

Cost Plus Pricing Method

It is donated by the summation of “unit cost” and “Expected percentage of return on costs”. It is comparatively less helpful in identifying inefficient practices that comes in the way of pricing techniques as compared to the TSCC model. (Appendix 2 shows the block diagram of TSCC model)

Question-5

To oversee business actually, O&M need following assistance from its accomplice (VM) to deal with its business effectively; firstly, it is important to build strong vendor relationship and consumer trust. The adequate information of supplies with proper contract, alternate courses of action, and compelling programming to help the relationship are also important in order to manage the business effectively.

Question-6

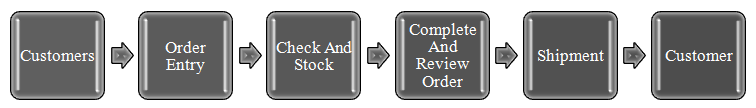

Information Flow Diagram

Question-7

An effective supply chain management includes a lot of important parameters that procure the company to the extreme success. The key benefits that VM procured through cooperation networks incorporates;

- Quality improvement

- Ordinary learning

- Decrease in average season of patients to meet physicians or to stay in hospital

- Decrease in monetary measurements

- Increase viability and performance

Question-8

The two principal objectives of supply network measurements are to increment usefulness and further develop consumer loyalty. The following are the main boundaries that would include in the conjecture model; these are

- On-time and damage free delivery

- Cash-to-cash cycle time

- Customer order cycle time and rate

- Warehousing cycles and expenses

- International and financial occasions

- Delphi strategy

- Authentic examination

- Board agreement

- Market research

Question-9

Risk Pooling

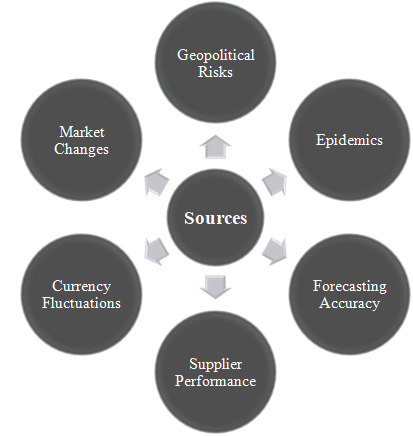

Risk pooling is the assortment and the executives of monetary assets to anticipate the covered up and erratic monetary risks and are disseminated among all individuals from the pool. The impact of risk pooling happens when the stock is held at incorporated area which permits the interest fluctuation at every retailer to be consolidated. There are several factors in which risk pooling should be considered when making the important decisions; these factors are

Product Flow and Warehouse Location

The choices on whether to have many stockrooms near the clients or more incorporated areas ought to consider the risk pooling impacts. The centralized product in one significant location can make aggregate advantage for the chain.

Transportation

The transportation cost could be quite cheaper if the products would be more considerate and sent in larger batch.

Push-Pull Strategy

This means that the part would only be assembled and manufactured if there shows a good demand in the environment and high customer ratio.

Design of a Product

The decisions on number of choices and complications in items can profit from risk pooling contemplations.

Sources of Risks

Risk Pooling in Practical Life

The primary drivers of inventory network are the compelling item offering, acquisition, assembling system and conveyance techniques. It is vital to adjust the compromise strategy through various measurable choice and logical programming.....

order your own originally done case solution."}" data-sheets-userformat="{"2":14913,"3":{"1":0},"9":0,"12":0,"14":{"1":2,"2":3355443},"15":"\"open sans\", Arial, sans-serif","16":10}">This is just a sample partial case solution. Please place the order on the website to order your own originally done case solution....

Supply Chain Partners Virginia Mason and Owens & Minor (A) Case Study Solution

This is just a sample partial case solution. Please place the order on the website to order your own originally done case solution.