Ace Designers – Competing Through Process Improvement Case Study Solution

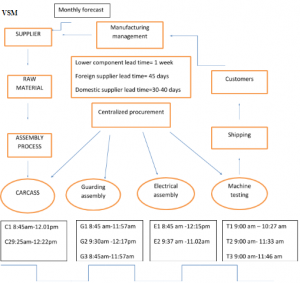

Value stream mapping (VSM)

In order to identify any loop-hole of the index mapping system and to optimize it further before implementing it into other product lines; it is essential to conduct the value stream mapping to identify any further cost reduction opportunities in the Jobber LM elite line.

The value stream mapping tool will help in creating positive changes in the processes and will help in bringing constructive changes in the organization while developing system wide benefits in cost, flexibility and quality.

In order to conduct the VSM, each of the station in the line was categorized in order to evaluate each of the working station. The whole process was tied together and the certain key metrics were calculated for each of the workstations and the assembly line as a whole, in order to identify any loop holes and the gap associated with the new system.

Through the VSM it was identified that the some of the stations required far less time to complete the assigned activities than other stations, as some stations had contract operators while other had trainees. Apart from that, it was also revealed that the company was not able to accurately forecast the demand due to which the company often suffered from slot losses to fulfill the high demands, mainly due to lack of raw material availability and insufficient labor.

Furthermore due to the increased requirements of raw material; the company was not able to manage the supply of the raw materials, leading to delays. Despite the fact that in order to make their procurement efficient; the company reduced the replenishment time from 15 days to one week, but still the company encountered with delays in the supply, as most of the suppliers were comparatively small players and did not possess the expertise.

Apart from that, the inventory management estimated at least a 30% decrease in the space requirement because of the issues that were arising mainly due to the space constraints on the assembly and sub-assembly lines as most of the components needed to be stored on the shop floor. (Exhibit 1)

Alternatives

In order to resolve any remaining issues that had the potential to limit the success of the new system implemented by Ace designers; following alternatives should be considered in order to optimize the system and to make further cost reduction for an aim to achieve price competitiveness.

Alternative 1

In order to accurately forecast the demand of the product line; the company should use the average growth rate of previous sales.

Pros

- This will help in forecasting the actual demand and will save the company from incurring any losses mainly due to inaccurate forecasting.

- It will make the company efficient in fulfilling all the orders planned for the Jobber LM Elite.

Cons

- The cost of raw material will increase by significant margin making it difficult for the company to manage the cost of operations.

- Most the suppliers are comparatively small and do not possess the required expertise to scale up with the growing needs of the company.

Alternative 2

The company should opt for decentralized procurement strategy instead of centralized procurement system.

Pros

- Decentralize procurement will help the company to meet the raw material requirement of each product line individually without compromising the needs of other plants.

- Each procurement manager will individually handle the requirements of the components, thus saving the company from any shortage of components while making the entire procedure efficient.

Cons

- Decentralized procurement will give more authority to the managers in managing each of their plants, this step will make it challenging for the company to keep the control over the suppliers due to multiple orders rather than ordering in large quantity.

- Multiple orders will increase the complexity and will make it difficult for the company to analyze the cost of operation for each of the plant.

- It will require large procurement team to manage the decentralized system effectively which will eventually increase the cost.

Alternative 3

Establishing relationship with big suppliers that possess the expertise to carry out the process improvement and can meet the requirement of raw material without any delays.

Pros

- This will help the company to meet the demand of raw material of each line in timely manner without any delays, resulting in improved profit margin.

- It will speed up the entire process and will help in fulfilling the sudden capacity expansion, eventually resulting in overall process improvement.

- Furthermore, it will also benefit the company by reducing the replenishment time for many of the components.

Cons

- In order to establish relationship with big suppliers; the company will be required to purchase the components in significant quantity that will further increase the need of more space, shortage of which is being currently faced by the company.

- This will also increase the cost being incurred by the company due to the little profit margins.

Recommendation

After evaluating the current scenario of the company and all the available options; it is recommended that Ace designers should opt for alternative 2, which is decentralized procurement strategy. This will make the half day indexing much more efficient. Although, the company will be required to hire some more staff in order to manage the procurement of each plant but eventually this will help the company in managing the needs for raw material more effectively. Apart from this, it will reduce the need of space requirement by reducing the level of duplication as the inventory will only be stored on the shop floor as per the requirement and need of each of the plant manager.

Exhibits

Exhibit 1: